028 Stihil Chainsaw Manual

Hi, I'm a new member. I know I preaching to the choir, but this forum is a wonderful resource that has already helped me a lot. I bought a new-to-me Stihl 028 WB a couple of weeks ago. I paid 75 bucks with the saw in non-running condition (it would fire but not catch, and wouldn't even run on starting fluid). It was clean and didn't look abused.

Saw is hard to start but after starting, will cut until it gets hot and stops. Can anyone tell me where to get a shop manual. No Stihl dealer nearby.

The price was reasonable so I decided to take a gamble. From the exhaust ports the piston has absolutely no scoring. Compression seemed good, but I didn't test it. Because the saw wouldn't run on ether, I assumed the ignition was the problem (it had points), and sure enough replacing points/condenser with a chip (I used the single-wire version) made it run. I also cleaned the carb, but seemed to be in pretty good shape. After adjusting the carb, the saw seemed to have a good, stable idle. It reved freely.

I then tried to cut wood. The saw runs well for a few minutes, begins to bog, and eventually, dies. The plug has a black film on one side. I will probably rebuild the carb (the diaphragms looked ok, but there could have been some wear on the tip of the needle). I suppose it's possible that the ignition chip is getting warm and making the spark weak or erratic, so I may replace the old chip/coil combination with an electronic ignition coil.

I have not pressure/vacuum tested the saw, so I may have a seal leak. Although the manifold boot and impulse tube look good, I did not remove them for a close inspection.

Naturally, I'd be grateful for any suggestions on solving the problem! One thing that would help in working on this saw are parts diagrams or even a service manual. Are there any online sources for these documents?

I do a lot of cutting with my vintage 044 Magnum. What a beast! We live in the middle of the region devastated by the Emerald Ash Borer and lost probably 30 trees on our property, including one that was more than 100 years old. I still have 8-9 more to fell. The 044 seems bulletproof (knock on wood), but it would be nice to have a reliable smaller saw to use for the light work.

I am sure I will have lots of additional questions in the coming weeks. Thanks again for this great forum! Is the man for IPL's and manuals.

There is a thread to ask for them on the forum. I have a routine I usually follow when I get a 'new to me' saw. After trying to start and run the saw, I usually pull the muffler and have a peak at the piston and the visible parts of the cylinder with a light. If there is no scoring, I reinstall the muffler and then do a Hillbilly compression check. Hold the saw by the pull cord and see if it easily goes toward the floor, if you find that there is some resistance, you have decent compression - it's at least enough to have the saw run and perform decent. Bogging off of idle or under a load can be a number of things, but at least you know it's most likely not the cylinder/piston at this point. From there you've already dealt with spark, so you have to sort out fuel and air.

I would say to clean the internal filter screen in the carb and check the fuel lines and impulse lines (where applicable). Make sure to check all the lines for pliability. You want them nice and supple. And, make sure there are no binds, kinks or cracks. After that, give it shot again and tune the carb.

Also, don't forget the in-tank filter. If it's partially clogged, you may be starving the saw for gas. I send this video to help guys get their carb in the ballpark.

Hi, I'm a new member. I know I preaching to the choir, but this forum is a wonderful resource that has already helped me a lot. I bought a new-to-me Stihl 028 WB a couple of weeks ago. I paid 75 bucks with the saw in non-running condition (it would fire but not catch, and wouldn't even run on starting fluid). It was clean and didn't look abused. The price was reasonable so I decided to take a gamble. From the exhaust ports the piston has absolutely no scoring.

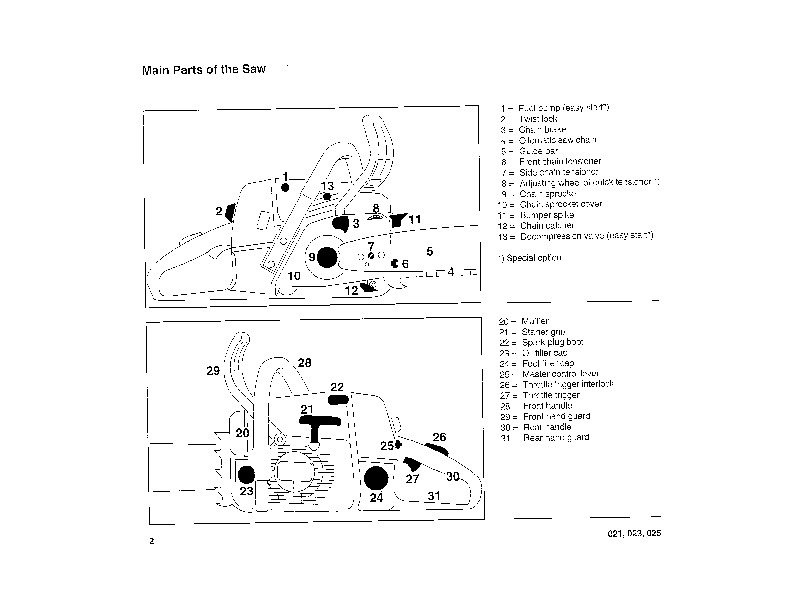

Compression seemed good, but I didn't test it. Because the saw wouldn't run on ether, I assumed the ignition was the problem (it had points), and sure enough replacing points/condenser with a chip (I used the single-wire version) made it run. I also cleaned the carb, but seemed to be in pretty good shape. One thing that would help in working on this saw are parts diagrams or even a service manual.

Are there any online sources for these documents? I do a lot of cutting with my vintage 044 Magnum. What a beast!

We live in the middle of the region devastated by the Emerald Ash Borer and lost probably 30 trees on our property, including one that was more than 100 years old. I still have 8-9 more to fell. The 044 seems bulletproof (knock on wood), but it would be nice to have a reliable smaller saw to use for the light work.

I am sure I will have lots of additional questions in the coming weeks. Thanks again for this great forum! Is the man for IPL's and manuals. There is a thread to ask for them on the forum. I have a routine I usually follow when I get a 'new to me' saw. After trying to start and run the saw, I usually pull the muffler and have a peak at the piston and the visible parts of the cylinder with a light. If there is no scoring, I reinstall the muffler and then do a Hillbilly compression check.

Hold the saw by the pull cord and see if it easily goes toward the floor, if you find that there is some resistance, you have decent compression - it's at least enough to have the saw run and perform decent. Bogging off of idle or under a load can be a number of things, but at least you know it's most likely not the cylinder/piston at this point. From there you've already dealt with spark, so you have to sort out fuel and air. I would say to clean the internal filter screen in the carb and check the fuel lines and impulse lines (where applicable). Make sure to check all the lines for pliability. You want them nice and supple.

And, make sure there are no binds, kinks or cracks. After that, give it shot again and tune the carb. Also, don't forget the in-tank filter.

If it's partially clogged, you may be starving the saw for gas. I send this video to help guys get their carb in the ballpark. Well, I got the 028 WB running and running well. I feel stupid about the bogging problem.

The fuel level in the tank was low. For some reason the new fuel line seems short and the new filter (both Stihl parts from my local dealer) is not very heavy (the one that came with the saw had a metal body). Slightly titling the saw to make a cut was enough to cause the engine to intermittently suck air. A full tank of gas solved the problem. The saw now runs great.

I used it to fell and buck three 12' dead white ash trees. I figure it's already paid for itself. If anybody near Louisville, KY, wants some free firewood, let me know! My first impressions of the saw are positive. I'm used to the 044, having used it for dozens of hours this spring cutting sea-grape trees (a very hard wood) felled by Hurricane Irma at our summer place in FL.

I run a 20' bar and full chisel chain on the 044. The saw itself is heavy and between the bugs, heat, and vibration, would beat me to death. Still doesn't recommend a full-chisel chain for the 028 and I'm using only a 16' bar with a new 'green-link' chain. The difference in power is noticeable, but so is the lower weight. The 028 AV system seems more effective than on the 044, and it is much, much easier to start.

While the 044 just demolishes trees regardless of the wood hardness or size, I can tell that the 028 will place a premium on keeping the chain sharp and paying attention to the geometry of the cut. One thing that concerns me about the 028 is its lack of a chain brake. Speaking of chains, the first chain I got from my Stihl dealer came apart while I was installing it! A tie strap right beside the green link fell right off. Looking closely at the chain, I could see that the pin ends for that link had not been upset.

I initially assumed that the dealer made up their own chains from a bulk roll, but they said it came that way from Stihl. The replacement was fine. I guess I'll look at the package tomorrow to where these chains are manufactured. Thanks so much for everybody's help in getting this saw up and running. Later this week I'll clean it up and post a photo. Is the man for IPL's and manuals.

There is a thread to ask for them on the forum. I have a routine I usually follow when I get a 'new to me' saw.

After trying to start and run the saw, I usually pull the muffler and have a peak at the piston and the visible parts of the cylinder with a light. If there is no scoring, I reinstall the muffler and then do a Hillbilly compression check. Hold the saw by the pull cord and see if it easily goes toward the floor, if you find that there is some resistance, you have decent compression - it's at least enough to have the saw run and perform decent. Bogging off of idle or under a load can be a number of things, but at least you know it's most likely not the cylinder/piston at this point. From there you've already dealt with spark, so you have to sort out fuel and air. I would say to clean the internal filter screen in the carb and check the fuel lines and impulse lines (where applicable). Make sure to check all the lines for pliability.

You want them nice and supple. And, make sure there are no binds, kinks or cracks. After that, give it shot again and tune the carb. Also, don't forget the in-tank filter. If it's partially clogged, you may be starving the saw for gas.

I send this video to help guys get their carb in the ballpark. Speaking of chains, the first chain I got from my Stihl dealer came apart while I was installing it! A tie strap right beside the green link fell right off.

Looking closely at the chain, I could see that the pin ends for that link had not been upset. I initially assumed that the dealer made up their own chains from a bulk roll, but they said it came that way from Stihl. The replacement was fine. I guess I'll look at the package tomorrow to where these chains are manufactured. Later this week I'll clean it up and post a photo. Click to expand.I saw the made in Switzerland notation on the box, but I was just shocked that it fell apart like that. What's even stranger is that it held together in the store when we stretched it out co compare with my old chain.

028 Stihl Chainsaw Manual

It only came apart when I was installing it on the bar. I was afraid company sold their chain in bulk rolls to dealers who then cut to length added a master link tie strap.

I guess the moral of the story is to check even new, high-quality chains before running 'em.